- Home Page

- Company Profile

-

Our Products

- Perforated Sheets

- Welded Mesh

- Woven Wiremesh

- Metal Perforated Sheets

- Perforated Coils

- Hole Perforated Sheets

- Perforated Circles

- Perforated Metals

- Perforated Tubes

- Perforated Wire Mesh

- Aluminum Sheets

- Metal Perforated Coils

- Metal Perforated Wire Mesh

- Wire Mesh

- Chain Link Fencing

- Welded Wire Mesh

- Stainless Steel Serving Tray

- Perforated Sheets For Building Facades

- Light Perforated Sheets

- Wire Mesh For Building Construction

- Aluminum Mesh

- Heavy Perforated Sheets

- Stainless Steel Screens

- MS Decking Plates

- Roofing Corrugated Sheet

- Woven Wire Cloth

- Perforated Sieves

- Galvanized Sheet

- Stainless Steel Wire Rope

- Fabrication Work

- Crimp Netting

- Precision Sheet Metal Components

- Galvanised Chain Link

- Perforated Strips

- Expanded Metal

- MS Base Plate

- Expanded Metal For Outdoor Fencing

- Perforated Belts

- Metal Screen

- Contact Us

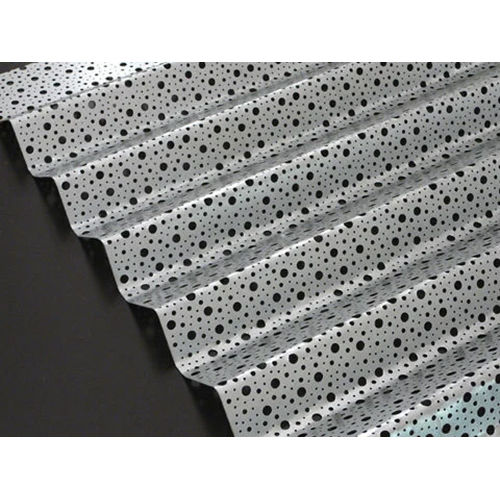

Perforated Corrugated Sheet

Perforated Corrugated Sheet Specification

- Surface Treatment

- Galvanized / Polished / Painted

- Roof Material

- Stainless Steel

- Usage & Applications

- Roofing, Cladding, Partitions, False Ceilings, Industrial Sheds

- Technics

- Cold Rolled, Perforated, Corrugated

- Height

- Customizable

- Features

- Anti-corrosive, Durability, High Strength

- Material

- Stainless Steel

- Tile Material

- Stainless Steel

- Tile Type

- Perforated Corrugated Sheet

- Type

- Roofing Sheet

- Size

- Standard and Custom Sizes Available

- Shape

- Rectangular

- Pattern

- Corrugated with Perforations

- Heat Transfer Coefficient

- Low (Good Thermal Insulation)

- Thickness

- 0.5 mm to 1.5 mm

- Length

- Up to 3000 mm

- Width

- Up to 1000 mm

- Acoustic Performance

- Sound Absorbing Perforation Design

- Installation Method

- Screwed / Riveted / Welded

- Corrosion Resistance

- Excellent

- Fire Resistance

- Yes

- Open Area Percentage

- 10% 50% (Depending on Perforation)

- Edge Finish

- Smooth, Deburred Edges

- Weight

- Lightweight Construction

- Hole Diameter

- 1 mm 10 mm

- Color

- Silver, Custom Colors Available

- Compliance

- Meets ASTM/AISI Standards

- Maintenance

- Low Maintenance, Easy to Clean

Perforated Corrugated Sheet Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 7 Days

About Perforated Corrugated Sheet

Product Details:

| Material | Aluminum, galvanized iron, mild steel, copper, brass, Steel / Stainless Steel |

| Surface Treatment | Galvanised, Color Coated, Coated |

| Features | Durable Coating, Corrosion Resistant |

| Technique | Cold Rolled, Hot Rolled |

| Usage/Application | Commercial |

| Thickness | 0.1 to 1.5 mm |

Acoustic and Thermal Efficiency

Designed with sound-absorbing perforations and low heat transfer coefficients, our corrugated sheets excel in both noise reduction and thermal insulation. This dual capability makes them an excellent choice for environments where comfort and energy efficiency are paramount, such as industrial sheds and commercial buildings.

Customizable Sizing and Surface Finish

Choose from a variety of standard dimensions or request custom sizes up to 3000 mm in length and 1000 mm in width. Our sheets can be supplied galvanized, polished, or painted, ensuring the right aesthetic and functional match for your specific project requirements.

Easy Installation and Low Maintenance

Installation is straightforward, with options for screwing, riveting, or welding. Thanks to high-quality stainless steel construction, the sheets require minimal upkeep, are easy to clean, and provide long-lasting durability, even in harsh outdoor environments.

FAQs of Perforated Corrugated Sheet:

Q: How is the perforated corrugated sheet installed for roofing and cladding applications?

A: The perforated corrugated sheet can be installed using screws, rivets, or welding methods. Its lightweight construction facilitates easy handling and secure attachment to structural frameworks, making it suitable for roofing, cladding, partitions, and ceilings.Q: What range of hole diameters and open area percentages are available in these sheets?

A: Our sheets offer hole diameters between 1 mm and 10 mm, with open area percentages from 10% to 50%, depending on the perforation pattern. This flexibility allows for tailored light, air, and sound permeability based on project needs.Q: When should I consider using perforated corrugated sheets with an acoustic design?

A: Opt for sheets with sound-absorbing perforations when noise reduction is a priority. These are particularly beneficial in factories, auditoriums, or commercial spaces requiring improved acoustic performance along with structural protection.Q: Where can these sheets be applied besides roofing?

A: Beyond roofing, the sheets are versatile for cladding, partitions, false ceilings, and industrial shed constructions. Their customizable design and structural strength make them suitable for both functional and aesthetic applications in various sectors.Q: What are the maintenance requirements and benefits of these stainless steel sheets?

A: The sheets are low maintenance, thanks to their corrosion-resistant stainless steel composition. They feature smooth, deburred edges for safe handling and are easy to clean, providing long service life even under harsh environmental conditions.Q: How do I order the sheets in custom sizes or colors?

A: You can specify custom dimensions (up to 3000 mm length and 1000 mm width) and choose from standard silver or request custom colors. Our team will assist you in selecting the right options for your project.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email